Shell Core: Manufacturer, Supplier.

Indo German Shell cast is renowned leader in manufacturing of Shell Core which are used for high quality ferrous and non- ferrous castings. We perform core making process in Core Shooter Machine or manually. Dedicated to excellence we are able to manufacture complex core designs which defines us as value added industry partner. Our Client focused approach ensures superior results in quality & reliability.

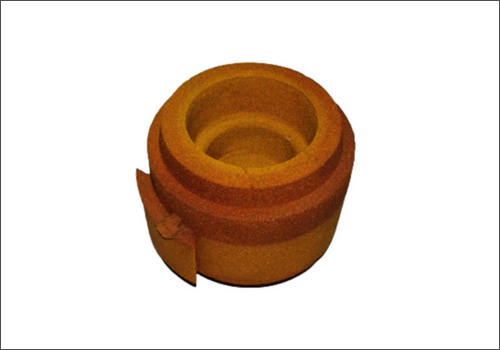

Shell Core Process:

We use Core Shooter Machine for production of cores which are then used in castings. The Machine operates by shooting a mixture of resin coated sand into corebox of desired shape, which moulds shell core in desired shape. The resin coated sand is shooted into heated corebox walls, which hardens forming layer upon layer into the mould cavity forming desired shape. The Shell Core is then ejected from corebox and can be diretctly used in Castings mould as core.

Advantages:

- High Dimensional Accuracy: Shell core achieves tight tolerance and precise dimensions required in core for quality castings.

- Smooth Surface Finish: The use of resin coated sand provides finishing which requires minimal casting machining in casting core.

- Capability Of Complex Shapes: This process allows core with complex shapes and detailed designs which is difficult to achieve in traditional methods.

- Faster Production rates: This process requires less time and efforts than the traditional approach, used for mass production.

- Minimized Defects: The absence of moisture in mould eliminates issues like bubbling & gas related defects.

Applications:

- Used in all kinds of Ferrous & Non- Ferrous castings as core.

- Automotive Industry: Shell core are used to produce critical components like engine blocks, cylinder heads, and transmission housings for vehicles.

- Aerospace Sector: They are essential for manufacturing complex parts such as aircraft engine blades and casings, ensuring high precision and durability.

- Industrial Machinery: Shell core are applied in creating gears and valves for heavy duty machinery requiring robust components.

- Construction Equipment: These type of casting is used in producing durable parts for construction machinery such as hydraulic systems and structural supports.

- Marine Applications: Shell core are employed in making corrosion resistant components like propellers and pump housings for marine environments.

- Energy Sector: They are used in wind power equipment and other energy related machinery requiring large, complex castings.