The term Sheet Metal refers to any metal that can be formed into flat pieces of varying thicknesses. Thick metals are called plate.

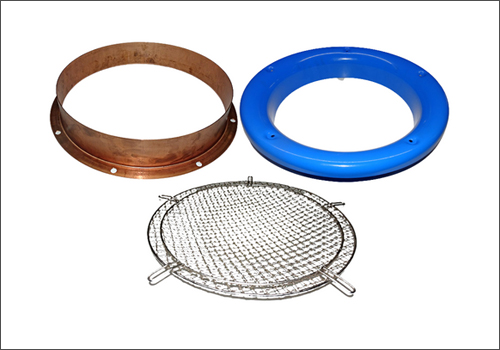

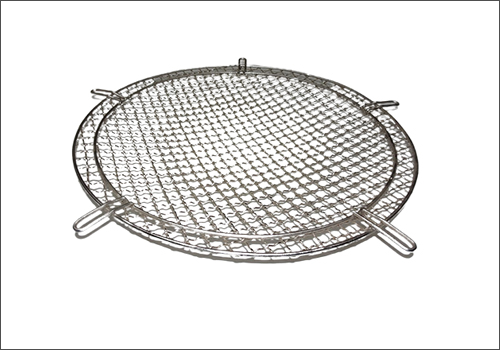

Sheet Metal Part Like SS, MS, Copper & Aluminum.

We use the following materials for Rubber Products

Indo German Shell Cast is a prominent manufacturer and supplier Sheet Metal Products. Renowned for our commitment to excellence, we deliver a diverse range of industrial products crafted from premium raw materials, ensuring durability and exceptional resistance to corrosion and abrasion.

Sheet metal is a versatile material used in various industries for its adaptability,durability and precision. Common materials employed in sheet metal fabrication include aluminum, brass, copper and stainless steel grades SS304, SS316 and SS410. Aluminum is lightweight, corrosion resistant and highly malleable, making it ideal for applications in aerospace, automotive and electronics industries. It is frequently used for body panels, roofing systems and enclosures. Brass sheet metal, composed mainly of copper and zinc, is valued for its oxidation resistance and refined design. It is often utilized in decorative applications like architectural elements, plumbing fixtures and musical instruments.

Copper sheet metal is prized for its excellent electrical conductivity and malleability.It is extensively utilized in electrical wiring systems, connectors, roofing panels and decorative designs. Stainless steel grades SS304 and SS316 are extensively employed due to their strength, corrosion resistance and hygienic properties. SS304 is widely used in food processing equipment, kitchen appliances and construction materials.SS316 offers enhanced resistance to chemicals and saline environments, making it suitable for marine applications and chemical processing equipment. SS410 stainless steel is a toughened alloy known for its high strength and wear resistance. It is often used in heavy duty industrial components such as gears, valves and pumps.

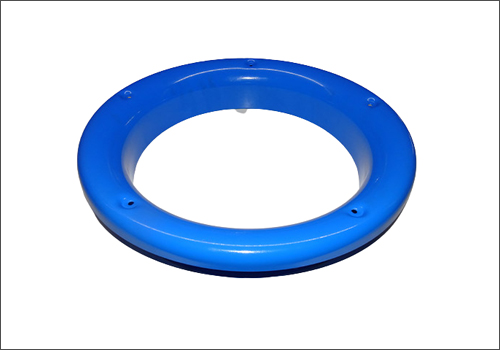

These metals are often bonded with rubber through processes like adhesive bonding to create composite materials that combine the flexibility of rubber with the rigidity of metal. Such combinations are extensively used in the manufacturing of gaskets, vibration isolators, diaphragms, seals and various industrial components. The integration of sheet metal with rubber enhances the mechanical properties of the final product while ensuring durability under harsh operating conditions.