Indo-German Shell Cast is a renowned and well-established in non-ferrous centrifugal casting in India. We specialize in manufacturing copper based alloy castings such as gunmetal, brass, phosphor bronze , magnesium bronze, aluminum bronze, silicon bronze and other specialized alloys.Our core focus is to deliver innovative, high quality products while meeting customer expectations through a consultative approach.

Centrifugal casting is a manufacturing process that uses centrifugal force to produce cylindrical components with high material integrity. The process begins with the preparation of a mold, typically made of metal or ceramic which is coated with a refractory material to withstand the high temperatures of molten metal. The mold is then rotated at high speeds, either on a horizontal or vertical axis, depending on the desired part configuration. Molten metal is poured directly into the spinning mold and the centrifugal force distributes the liquid metal evenly along the mold's inner walls. This force not only ensures uniform wall thickness but also drives impurities and lighter inclusions toward the inner diameter.

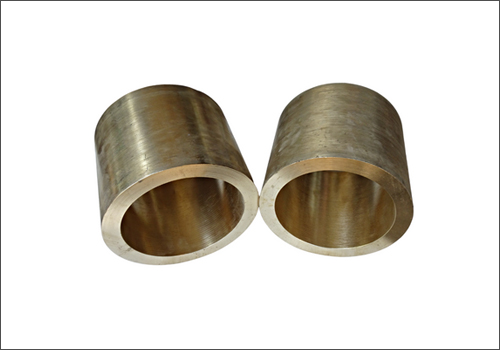

The rotation continues until the molten metal cools and solidifies, resulting in a dense, fine-grained casting with excellent mechanical properties. The process is highly versatile and can be used for metals such as iron, steel, aluminum, copper alloys and even concrete or glass. Centrifugal casting is particularly effective for creating thin walled cylinders, pipes,rings and other rotationally symmetric parts. After solidification, the mold is stopped and the casting is removed for post processing such as surface treatments.

There are three main types of centrifugal casting: true centrifugal casting, semi-centrifugal casting and centrifuge casting. True centrifugal casting is used for hollow cylindrical parts like pipes and tubes without requiring a core. Semi-centrifugal casting produces solid parts by using molds with cavities. Centrifuge casting involves molds with multiple cavities arranged around a central pouring channel to create smaller components simultaneously.